Heumader innovation

Automation

Heumader Innovation focuses on the automation of physical processes with the help of machines and control systems in order to speed up industrial processes. Both robots and non-robotic machines are used.

Industry 4.0

Industrial automation

Heumader Innovation specializes in the automation of physical processes with the help of machines and control systems to further accelerate industrial processes. This physical automation is achieved through the use of robots as well as semi-robotic or non-robotic machines (e.g. CNC machines).

Man & Machine

Intelligent networking

Heumader Innovation is also involved in the intelligent networking of machines and internal processes with the help of ICT (information and communication technology), which is widely known as Industry 4.0. This opens up many opportunities and enormous advantages for companies of all kinds: flexible production, optimized logistics, resource-conserving recycling management, customer-centric solutions, optimized use of data and versatile factories.

Mensch und Maschine

Innovative Steuerung & Roboter Peripherie

Heumader Innovation bietet Industrieroboter in zahlreichen Varianten und verschiedensten Traglasten und Reichweiten an.

Years of experience with customized solutions

Innovation meets precision

“At Heumader Innovation, the 4th industrial revolution has long since begun: Man, machines and products are directly connected and networked! Computer-aided automation has revolutionized the industry. With the Internet as the central technology, Heumader Innovation is continuing the global networking of digitalization in production.”

Our experts are there to help and advise you!

Are you planning a project in your company?

We will advise you individually and work with you to develop a suitable concept – tailored to your operational requirements.

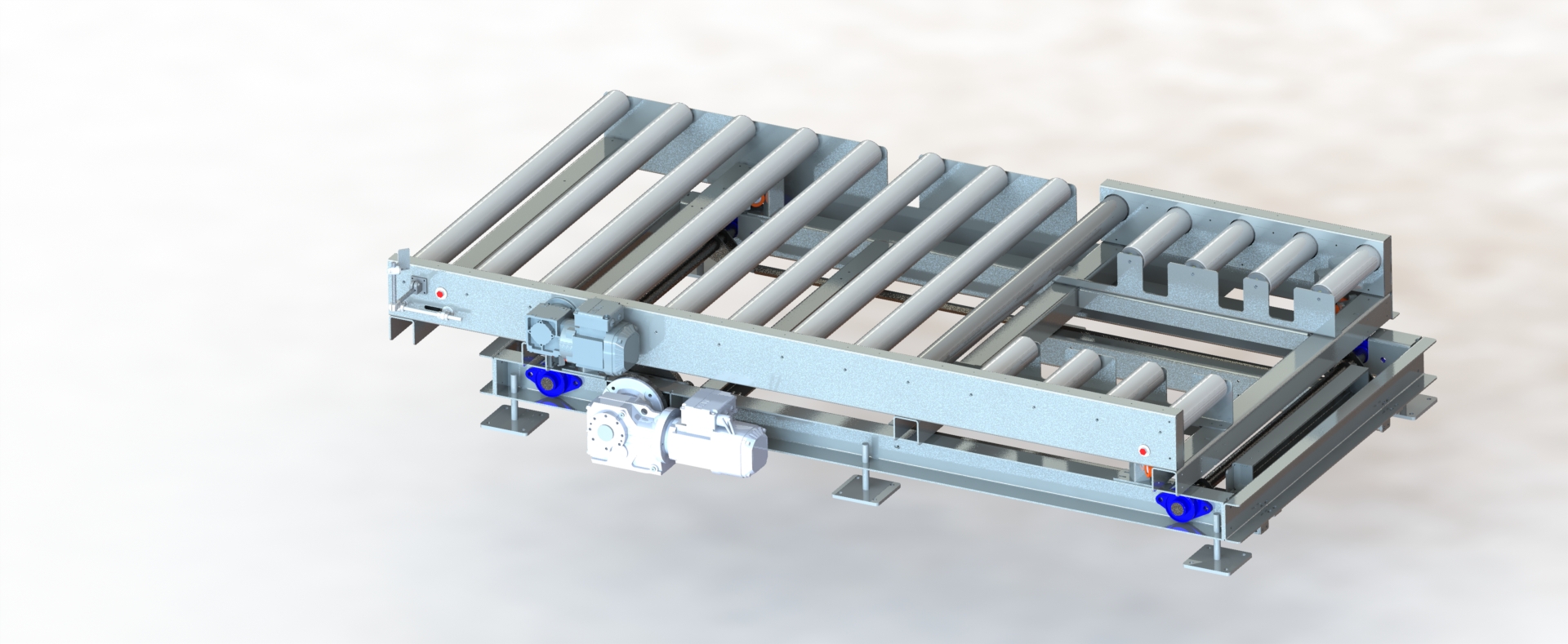

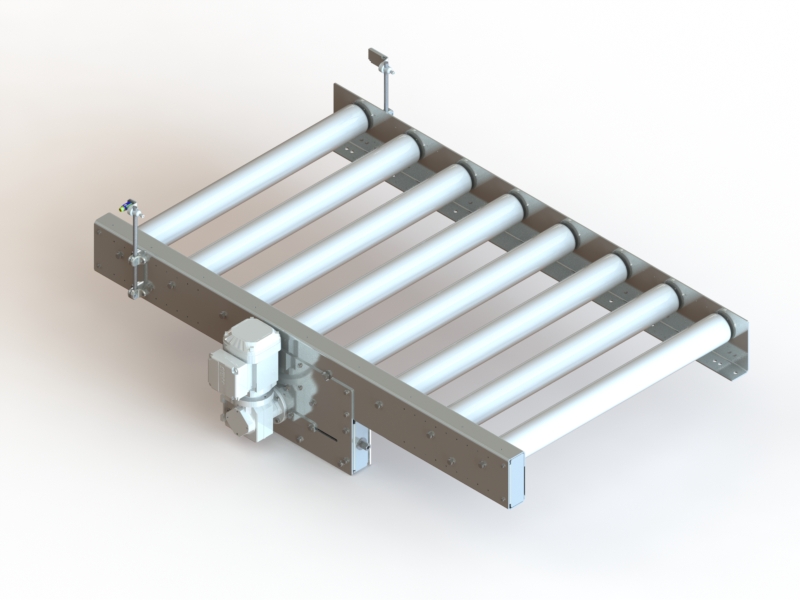

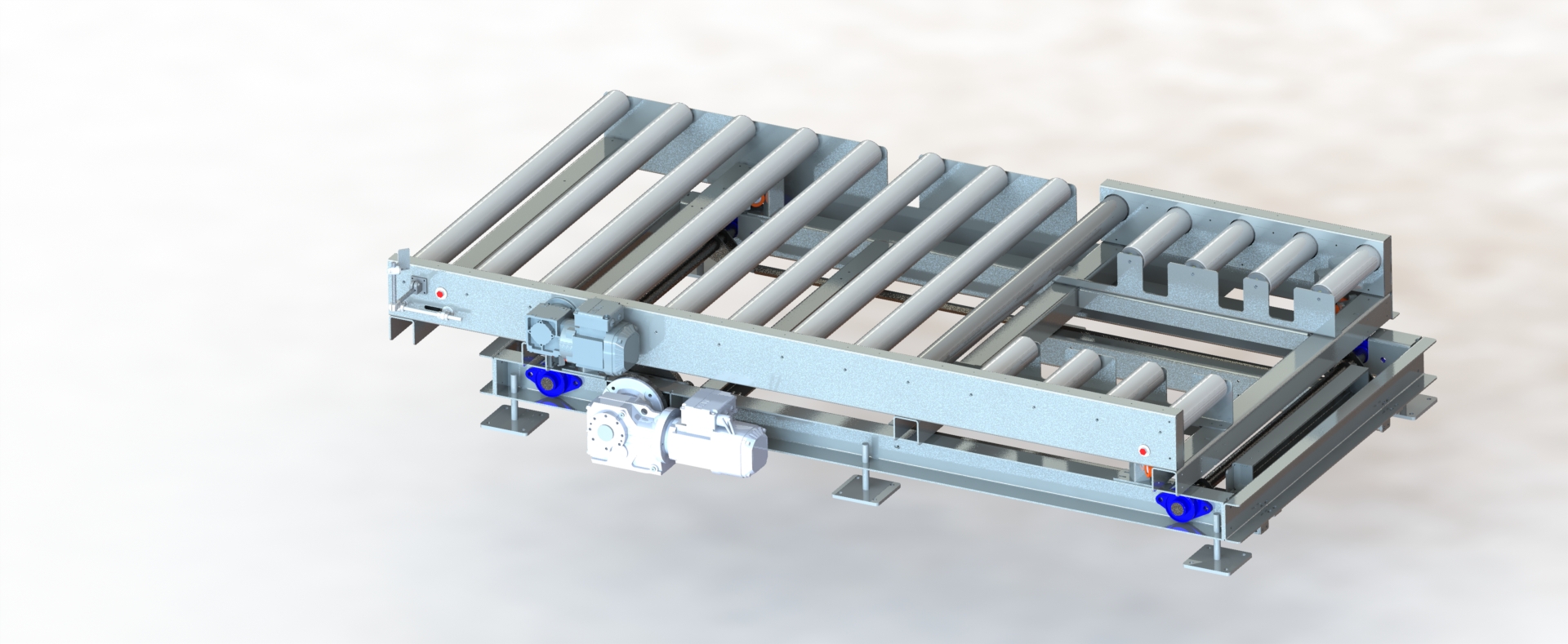

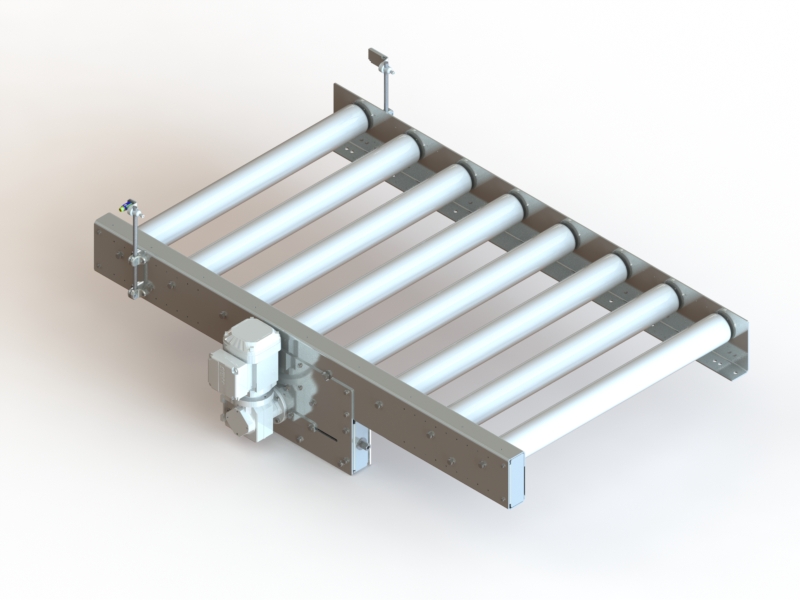

Roller conveyor

One of the key advantages of roller conveyors is their modular design, which can be expanded almost at will using complex conveyor systems. Roller conveyors mainly transport heavy unit loads that move on rollers.

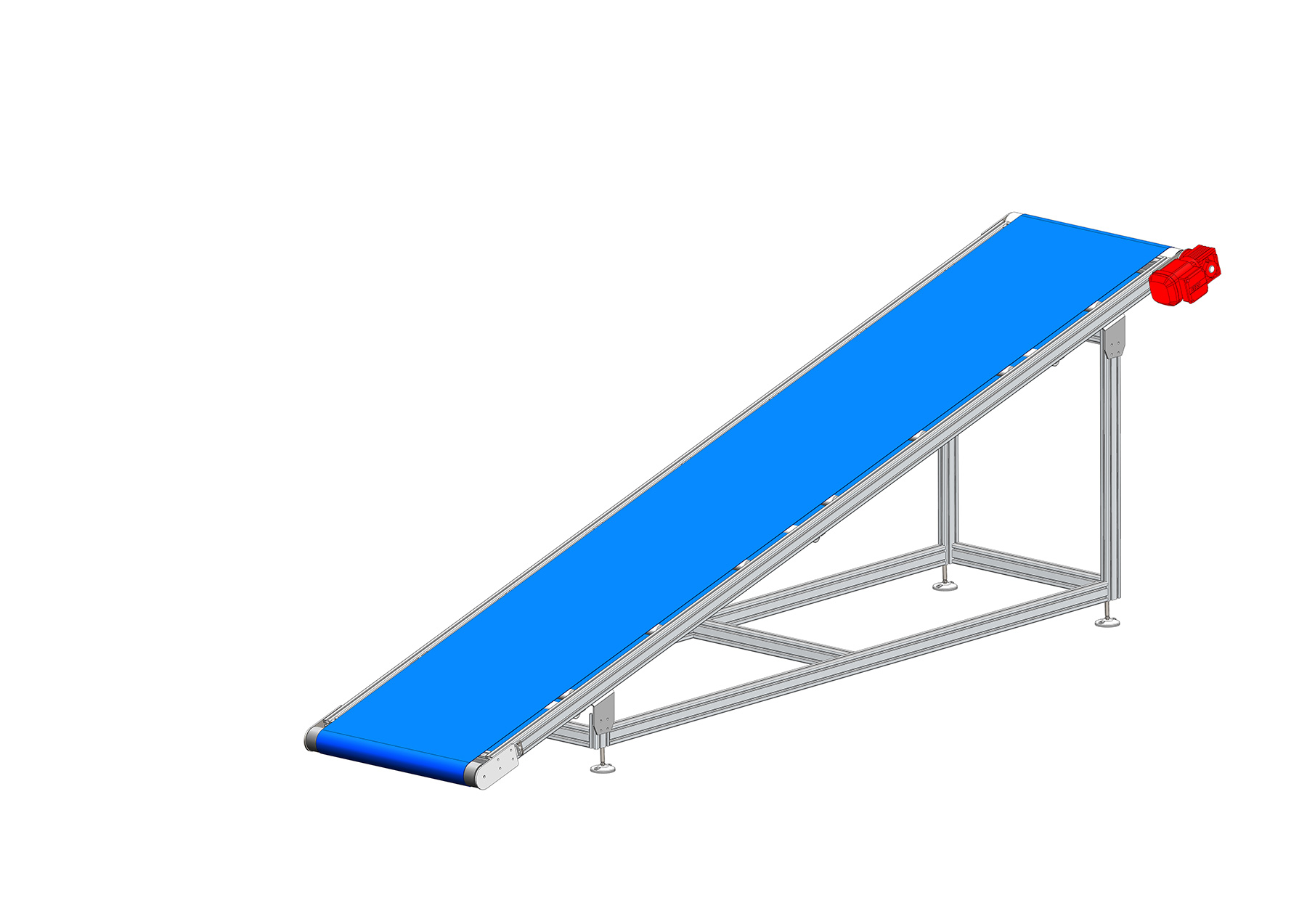

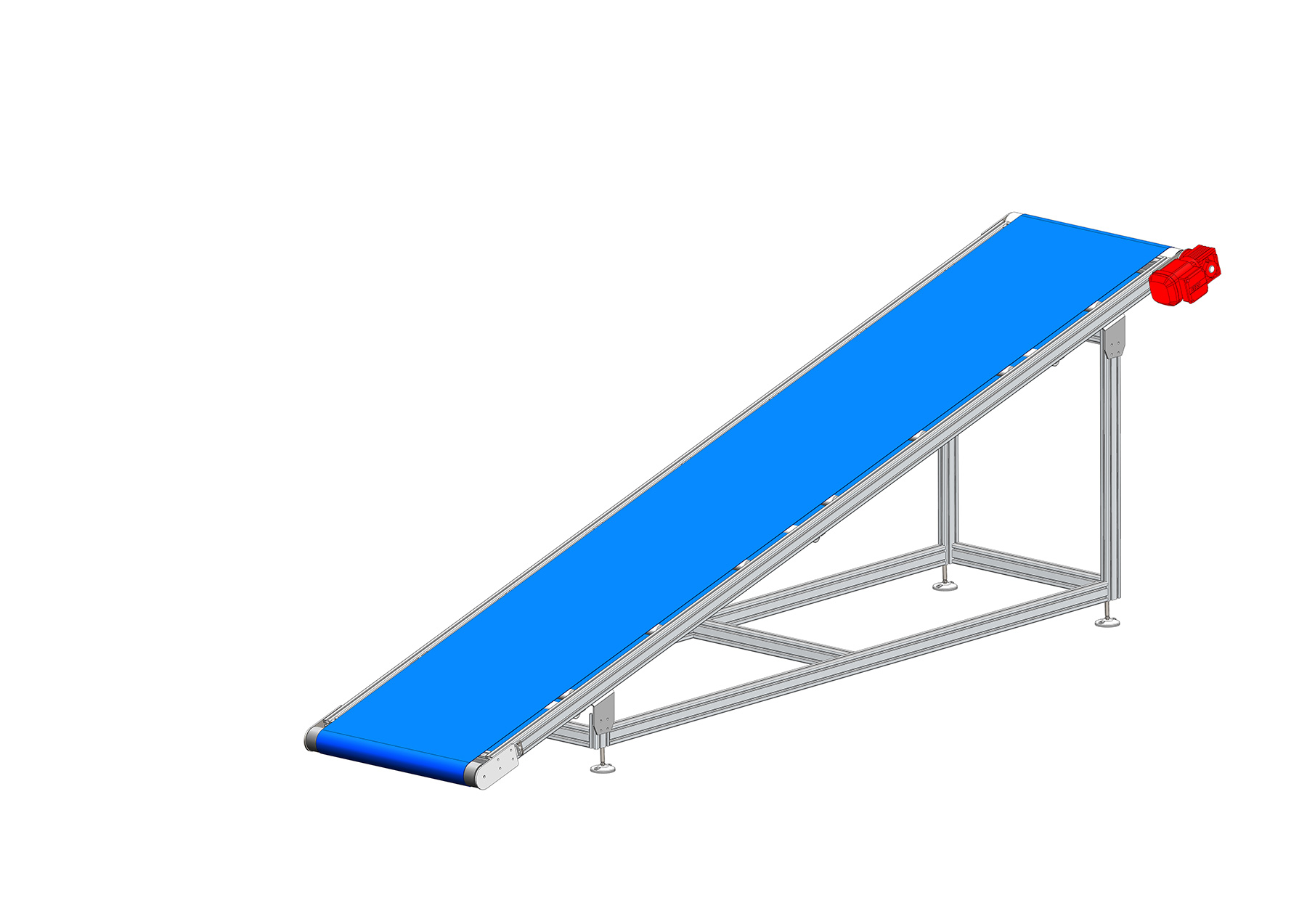

Ascending conveyor

A belt conveyor for the food industry was required for bar production. In addition, a frame is to be constructed where up to 5 dispensers can be mounted and adjusted. Each dispenser should function independently.

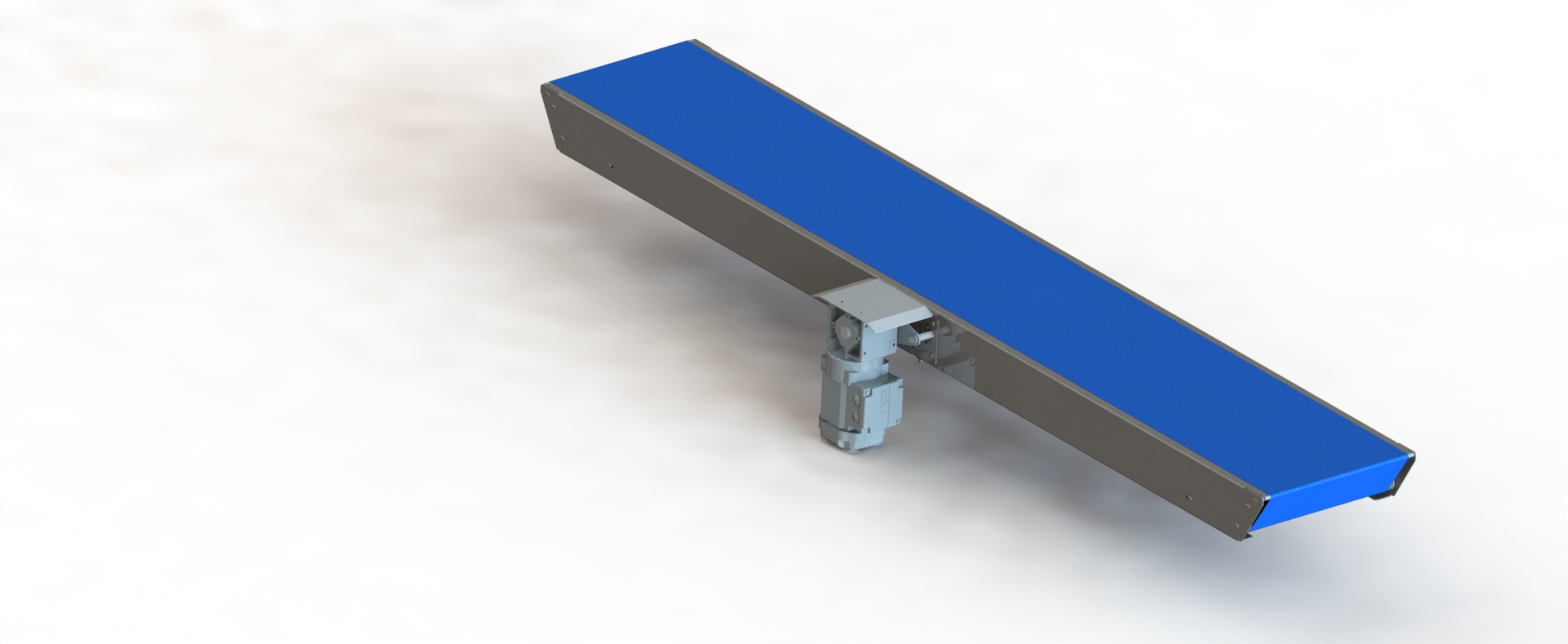

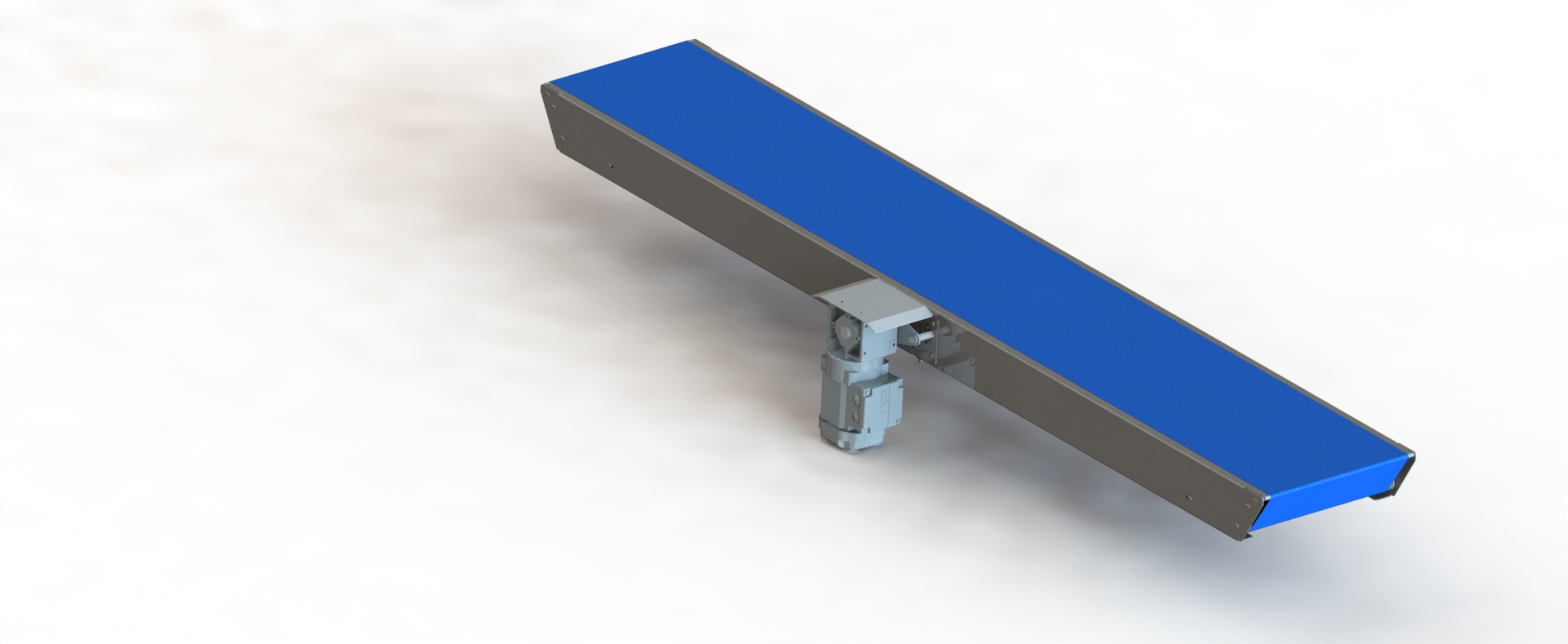

Belt conveyor

A belt conveyor for the food industry was required for bar production. In addition, a frame is to be constructed where up to 5 dispensers can be mounted and adjusted. Each dispenser should function independently.

Toothed belt conveyor

Mobile PV systems are relatively small but require heavy equipment to move the modules out of the container. We developed an automatic drive unit that transports the PV modules out of and into the container in a simple and safe way.

Buckling conveyor

Heumader Innovation installed an articulated conveyor between the cardboard cutting machine and the workstation to automatically transport the waste into a designated container.

Corner transfer unit

The corner transfer unit can transfer in both directions, right or left. The corner transfer unit is suitable for diverting cardboard boxes or flat transport goods.

Roller conveyor

One of the key advantages of roller conveyors is their modular design, which can be expanded almost at will using complex conveyor systems. Roller conveyors mainly transport heavy unit loads that move on rollers.

Ascending conveyor

Belt conveyor

A belt conveyor for the food industry was required for bar production. In addition, a frame is to be constructed where up to 5 dispensers can be mounted and adjusted. Each dispenser should function independently.

Toothed belt conveyor

Buckling conveyor

Heumader Innovation installed an articulated conveyor between the cardboard cutting machine and the workstation to automatically transport the waste into a designated container.