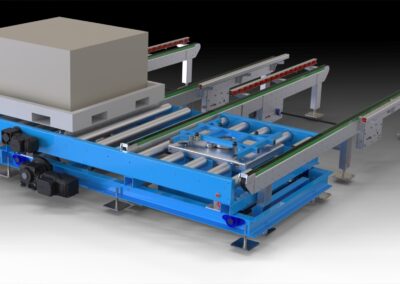

Conveyor line for steel containers

Assignment

The Containers are delivered to the container line with a Forklift or, at a later stage, with an AGV and lifted to the pick-up position. These Containers must then be separated using an automatic Destacker. After Separation, the Containers are automatically recognized on the Conveyor line and conveyed together without gaps.

A manual filling Station must be planned into which the Transport container automatically moves in or out when it is empty. When the Containers are fully loaded, the worker must be able to send this container to the removal position via a suitable release. There, the Containers are picked again so that 3 are stacked on top of each other and then conveyed to the removal position. The Containers are finally picked up at the removal position with a forklift Truck or at a later time with an AGV.

Realization

The Requirement was realized with various conveyor technology components. Chain conveyors are used for Transportation, eccentric lifting gear is used for height compensation and guides, which are electrically driven by a toothed belt, are used for stacking and destacking. The operators and forklift drivers are informed via LED strips as to whether they can intervene in the system or not. The system operates completely automatically and is protected by various safety mechanisms.