Heumader innovation

Conveyor elements

Heumader Innovation optimizes the material flow in the company: Conveyor elements and conveyor technology components are essential for any machine construction. Our conveyor technology helps you to transport your goods efficiently.

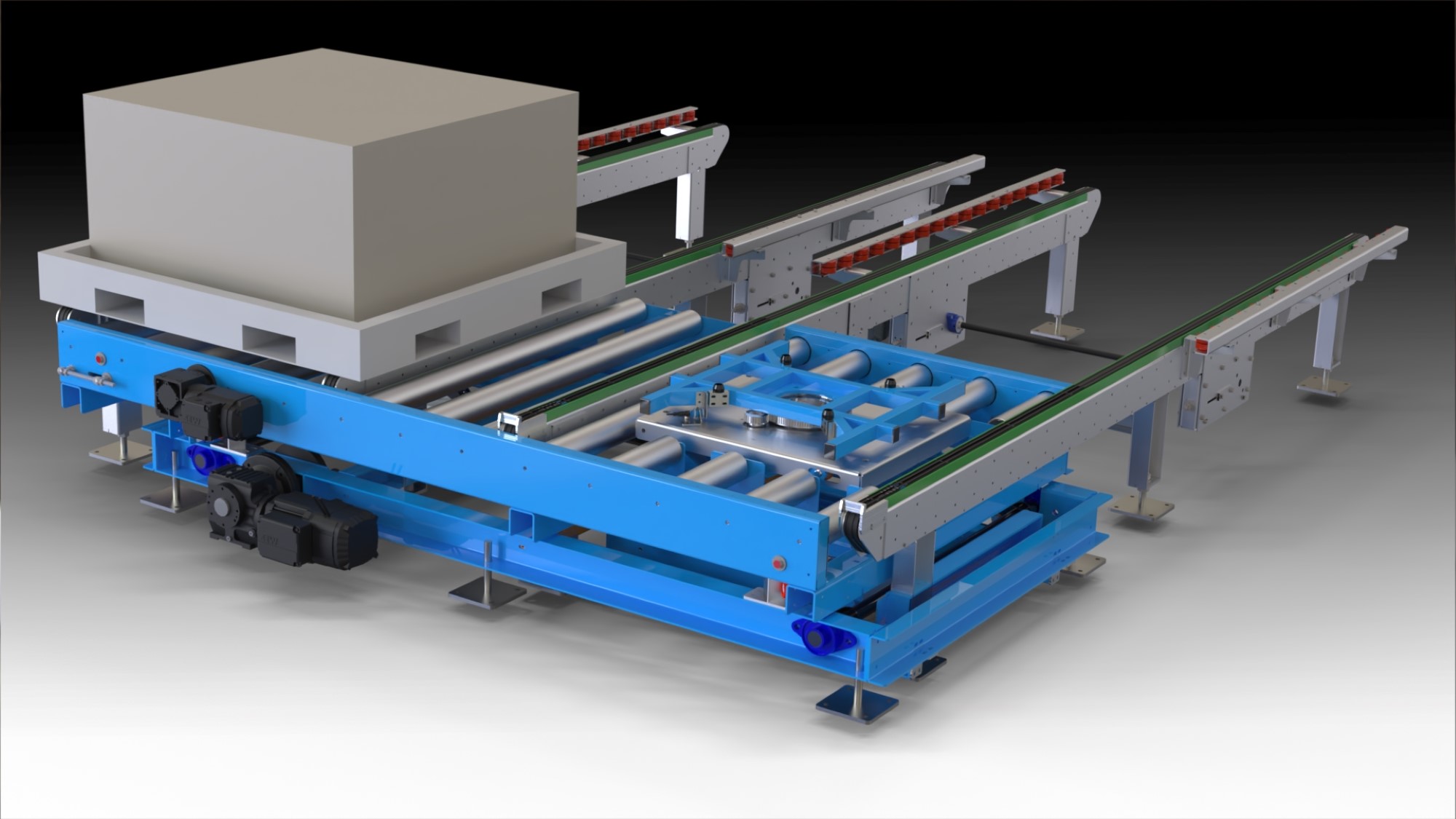

Roller conveyor

Stacker / Denester

Climb conveyor

Vertical conveyor

Toothed belt conveyor

Corner converter

The corner transfer unit can transfer in both directions, right or left. The corner transfer unit is suitable for diverting cardboard boxes or flat transport goods.

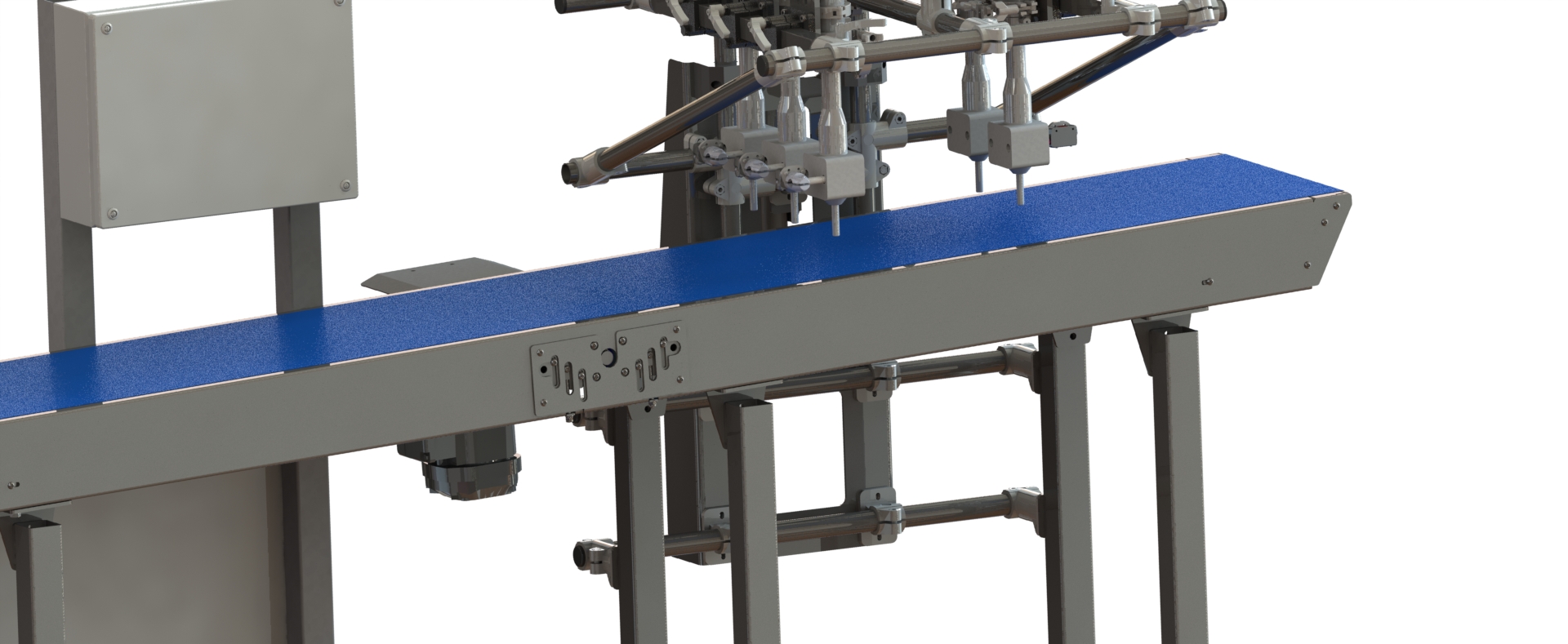

Belt conveyor

A belt conveyor for the food industry was required for bar production. In addition, a frame is to be constructed where up to 5 dispensers can be mounted and adjusted. Each dispenser should function independently.

Chain conveyors

Chain conveyors are driven by one or more chain strands. Due to the lower center of gravity, it makes sense to use a multi-track conveyor belt, especially for large, flat piece goods, as this ensures sufficient stability.

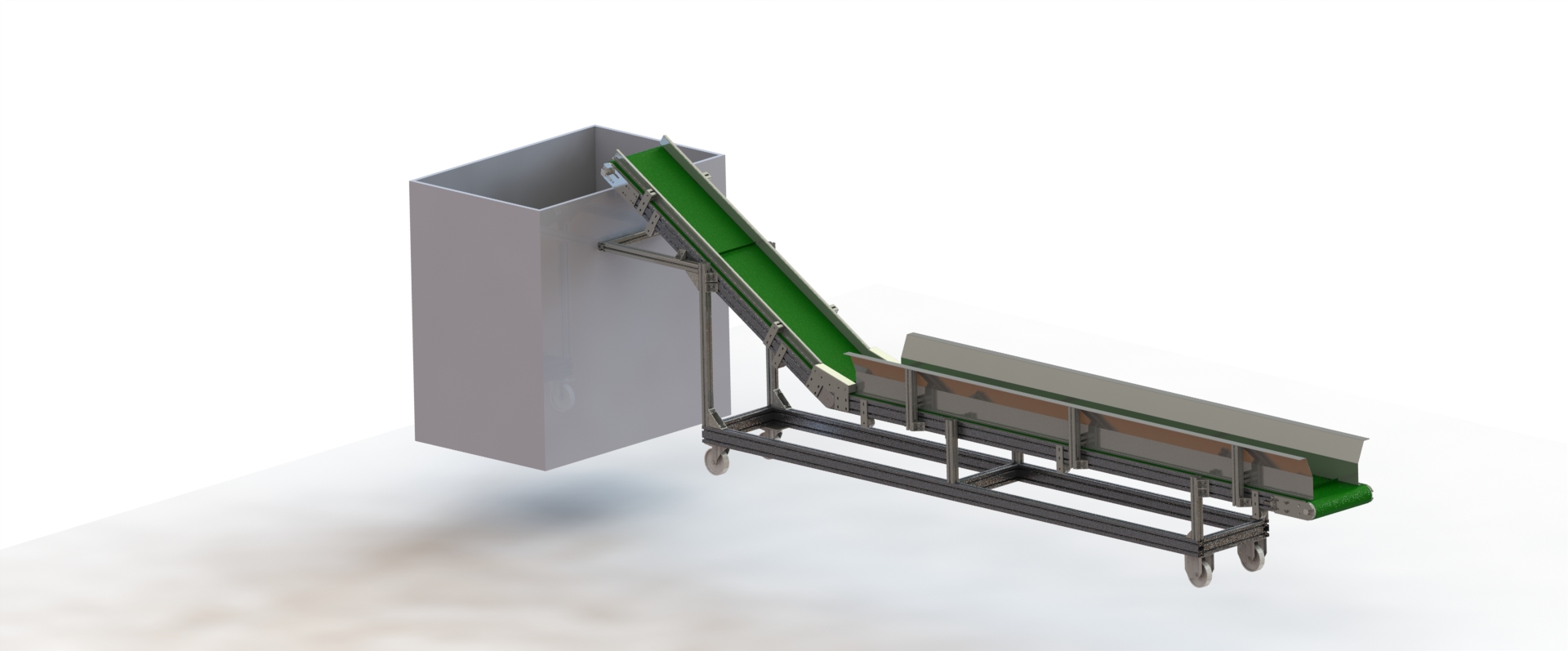

Buckling conveyor

The waste from a cardboard cutting machine was collected and emptied manually every hour. An articulated conveyor was installed between the cardboard cutting machine and the workstation to automatically transport waste to the designated container.

Modular belt conveyor

Modular belt conveyors are more wear-resistant than belts and can also be used where sharp-edged goods need to be conveyed. They are extremely robust and can be used for almost any transport application.

Conveyor technology that optimizes every material flow

Belt conveyors, modular belts, chain conveyors, roller conveyors and many more of our individual conveyor components help you to transport your goods, products and food.

Roller conveyors

One of the key advantages of roller conveyors is their modular design, which can be expanded almost at will using complex conveyor systems. Roller conveyors are mainly used to transport light or heavy unit loads that can be transported on rollers.

Stacker / Denester

The containers are delivered to the container line with a forklift or an AGV and lifted to the pick-up position. The automatic destacker separates the containers, which are then automatically recognized on the conveyor line and conveyed together without gaps. The transport container moves in and out automatically. The worker can then send the container to the removal position via a suitable release.

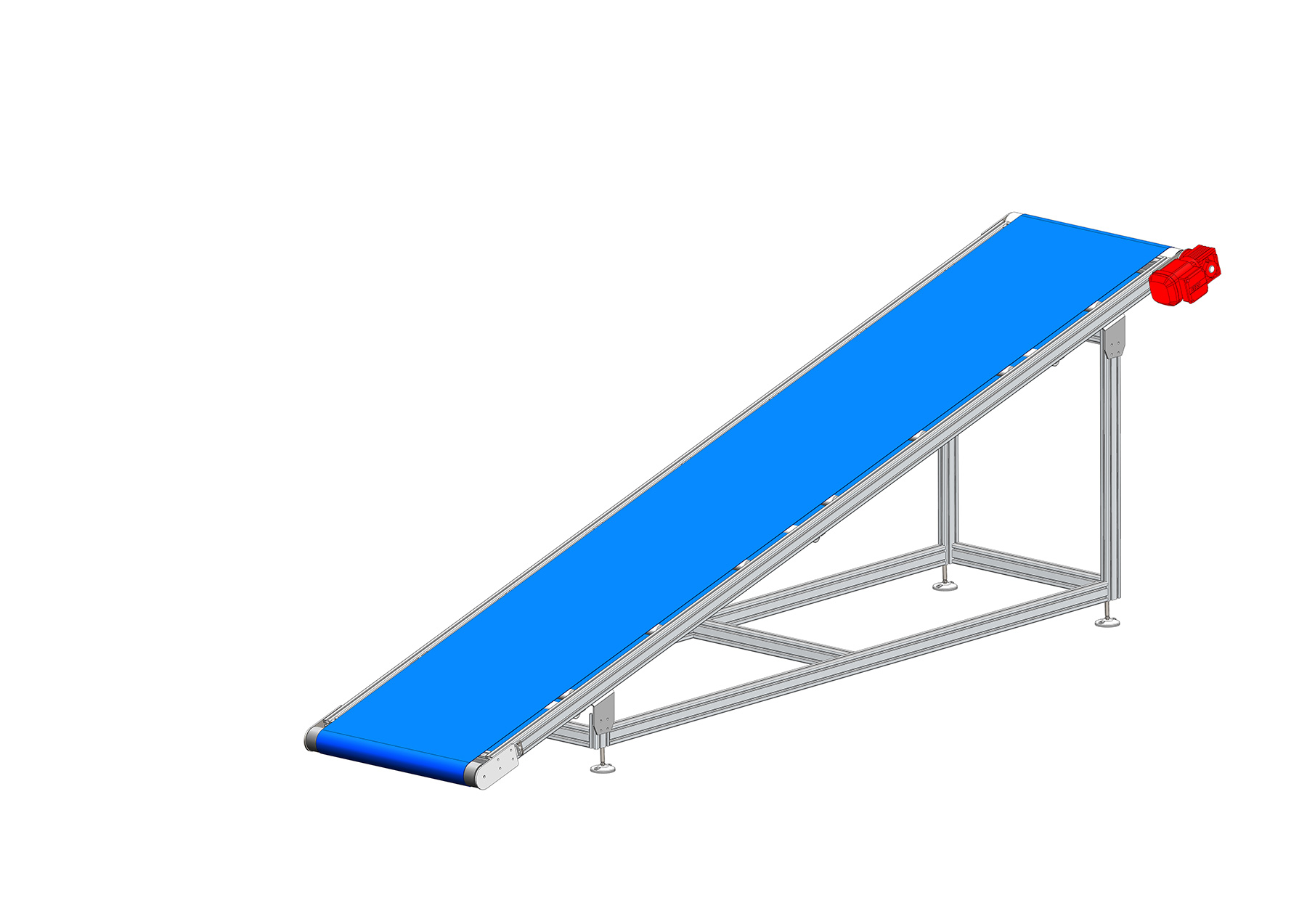

Ascending conveyor

Ascending conveyors are used to transport bulk materials or unit loads vertically or diagonally upwards. They are particularly practical when materials need to be lifted above a certain height. Typical areas of application are agriculture, where grains or seeds are conveyed, for example. Ascending conveyors are also used in logistics and production, for example when conveying parcels or components.

Vertical conveyor

A vertical conveyor is part of a conveyor system within a material flow system and is installed in horizontal conveyor lines and is used to lift goods to a higher or lower level.

Toothed belt conveyor

Mobile PV systems are relatively small but require heavy equipment to move the modules out of the container. We developed an automatic drive unit that transports the PV modules out of and into the container in a simple and safe way.